Subtotal: $369.00

Types of 3d Printing technologies Leave a comment

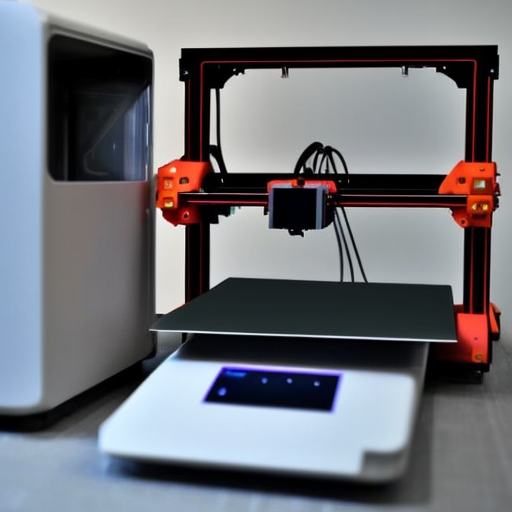

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is an additive manufacturing technology used to create 3D objects. FDM works by extruding a thermoplastic filament through a heated nozzle and depositing it layer by layer onto a build platform. This process is also known as filament deposition modeling.

FDM is well known for its low cost and relatively easy setup. FDM is great for prototyping and producing small parts quickly. It is also one of the most popular 3D printing technologies used in the consumer market.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is an additive manufacturing process used to create 3D objects from a powder material. In this process, a laser is used to selectively sinter the powder powder material together to form the desired shape.

SLS is great for producing complex parts with high accuracy and detail. It is also one of the most cost-effective technologies for producing large parts.

Digital Light Processing (DLP)

Digital Light Processing (DLP) is an additive manufacturing technology used to create 3D objects from a liquid resin. In this process, a DLP projector is used to selectively cure the resin layer-by-layer to form the desired shape.

DLP is great for producing detailed parts with high accuracy and resolution. It is also one of the fastest 3D printing technologies available.

Stereolithography (SLA)

Stereolithography (SLA) is an additive manufacturing technology used to create 3D objects from a liquid resin. In this process, a UV laser is used to selectively cure the resin layer-by-layer to form the desired shape.

SLA is great for producing detailed parts with high accuracy and resolution. It is also one of the most popular 3D printing technologies used in the consumer market.

PolyJet 3D Printing

PolyJet 3D Printing is an additive manufacturing technology used to create 3D objects from a liquid resin. In this process, a UV light is used to selectively cure the resin layer-by-layer to form the desired shape.

PolyJet 3D Printing is great for producing detailed parts with high accuracy and resolution. It is also one of the most cost-effective 3D printing technologies available.

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) is an additive manufacturing technology used to create 3D objects from a powder material. In this process, a series of jets are used to selectively build the powder material layer-by-layer to form the desired shape.

MJF is great for producing complex parts with high accuracy and detail. It is also one of the most cost-effective technologies for producing large parts.

Benefits of 3D Printing Technology

3D printing technology is becoming increasingly popular due to its numerous benefits. Some of the benefits of 3D printing technology include:

Cost Savings – 3D printing technology is a cost-effective way to produce parts and prototypes. It eliminates the need for expensive tooling and allows for faster production times.

Flexibility – 3D printing technology can produce parts and prototypes with complex geometries and intricate details. This allows for more design flexibility and quicker prototyping times.

Scalability – 3D printing technology can be scaled to produce parts and prototypes in any size or quantity. This makes it ideal for small-volume production runs and rapid prototyping.

Sustainability – 3D printing technology is environmentally friendly due to its low energy consumption and minimal waste production.

FLASHFORGE Adventurer 3 3D Printer Leveling-Free with Quick Removable Nozzle and Heating Bed, Built-in HD Camera, Wi-Fi…

FLASHFORGE Adventurer 3 3D Printer Leveling-Free with Quick Removable Nozzle and Heating Bed, Built-in HD Camera, Wi-Fi…